Your master supplier for Blown Film Controls:

- Smart, Dependable & Focused Solutions

- Fulfilled Project Goals

- On Time Delivery

- Expert Level Service / Support

With over 35 years of experience, we are here to provide proven film width and thickness control solutions to the blown film extrusion industry. You can get a quick look at how we can help by viewing this 3 minute video.

TDK-500 Automatic Air Ring with InstaGauge™ Control System

Faster

Unique Upper Lip Air Modulation for fast, precise gauge control

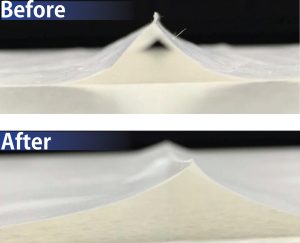

Flatter

Flatter Film, Less Waste, Improved Processability

Easier

Mechanical innovations for improved ease of use, maintenance and set-up. A more approachable automatic air ring!

Video not visible? Please activate cookies to view embedded media (bottom left cookie icon).

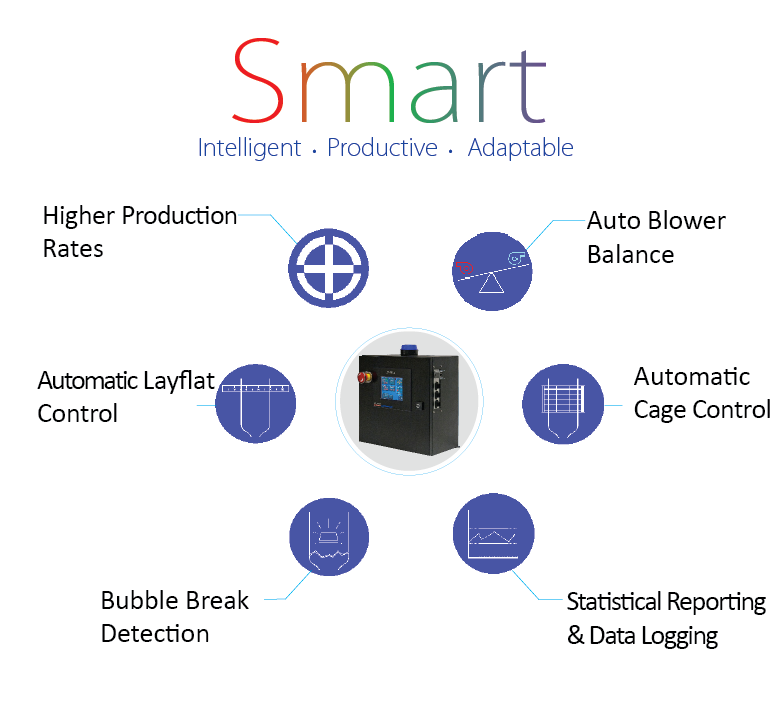

Internal Bubble Cooling - A powerful, 4th Generation upgrade for high speed, precision IBC control, packed with automated features.

IBC Made Easy

Minimal Operator Training

Smart IBC

A Performance Boost for Blown Film Lines. Automate the Tough Jobs

Track Record and Reputation

World Leader in IBC Control

Solve: Poor internal bubble cooling control, low production rates, width variation, lack of skilled operators

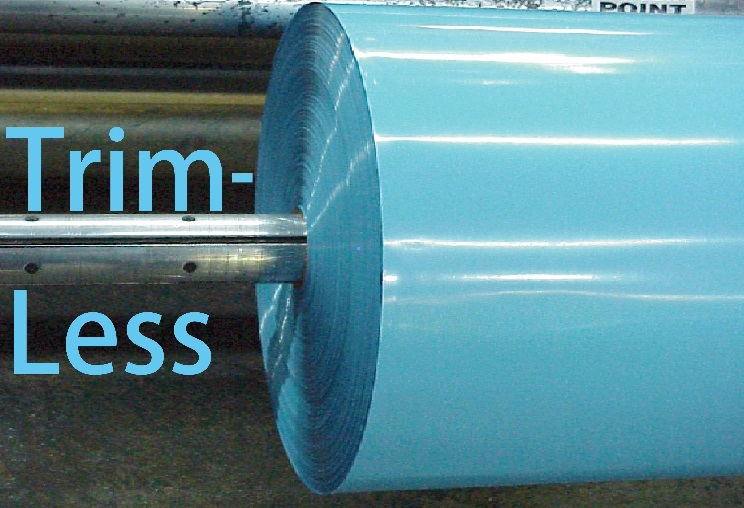

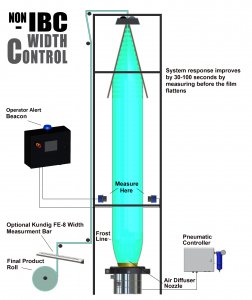

Auto-width control for lines without IBC. Reduce trim & downtime, increase profitability & reliability

The video to the right demonstrates how we achieve width control in a precise and reliable manner for all nonIBC lines.

Solve: Line Downtime on nonIBC Blown Film Lines, Width Control, Scrap Production

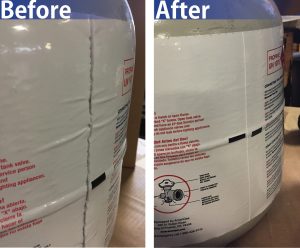

Machine Direction Sealing - Superior solution to the slit seal for reliable & strong MD film sealing

Solve: Film seal failure, unreliable sealing, rough seal edges, sealed roll geometry, seal process speed

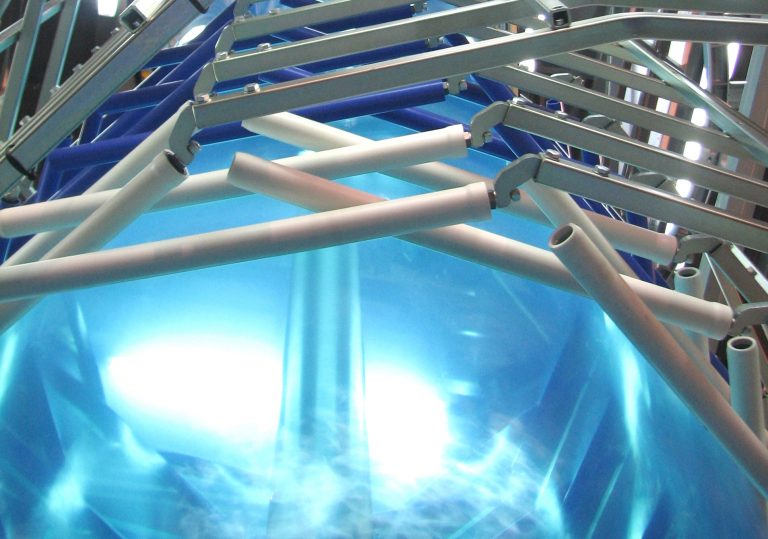

Radial sizing cages for superior bubble stability & mark-free holding power

- Perfect Support for Both Large and Small Bubbles

- Radial Actuation Provides Better IBC Sensor Placement

- Protected Roller Bearings for Low Inertia Contact

- Range of Roller Covers for All Film Types

- Little to No Maintenance

Solve: Poor bubble stability, scratched film, constant roller maintenance

Air chilling solutions: Efficient cooling coils & direct air chilling solutions

Chill Process Air to 40°F / 4.5°c

Increase Production with Cooler Air, Improve Film Clarity, Dehumidify Air

Temperature Control to +/- 0.2°F

Control Process Air Precisely for Improved Bubble Control

Energy Efficiency

Inverter Controlled Compressor for 50% Improved Energy Efficiency

Solve: Low cooling rates, film clarity issues, cooling energy efficiency, aging chiller systems

Latest News

New Developments

New Features, Upgrades, Performance Add-Ons and more

Upgrade your lines performance

Learn MoreTradeshows & Events

Upcoming tradeshows, seminars and conferences

Meet with us, or attend a training seminar

Learn MoreNewsletters

Read about industry trends, tech tips and company developments

Gain perspective and save time / money with helpful tech tips

Learn More