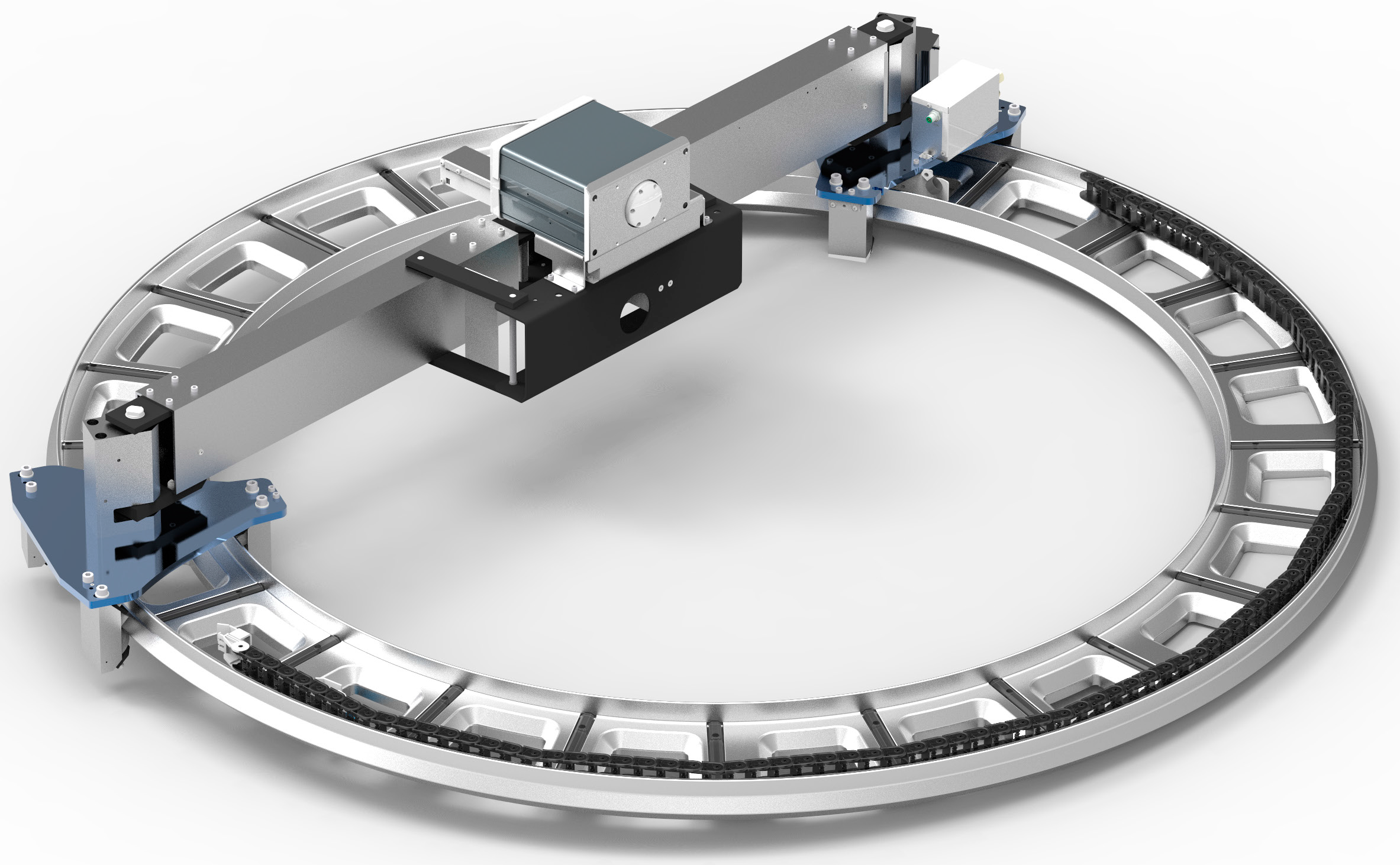

TDK-500 Automatic Gauge Control Air Ring

Automatic Air Ring – TDK-500

This product is protected by the following USA, Canada, and EU patent/applications:

US11,618,200 CA3,077,704, US11,826,941, EP4,299,277 and other patents pending.

Flatter Film, Less Waste, Improved Processability

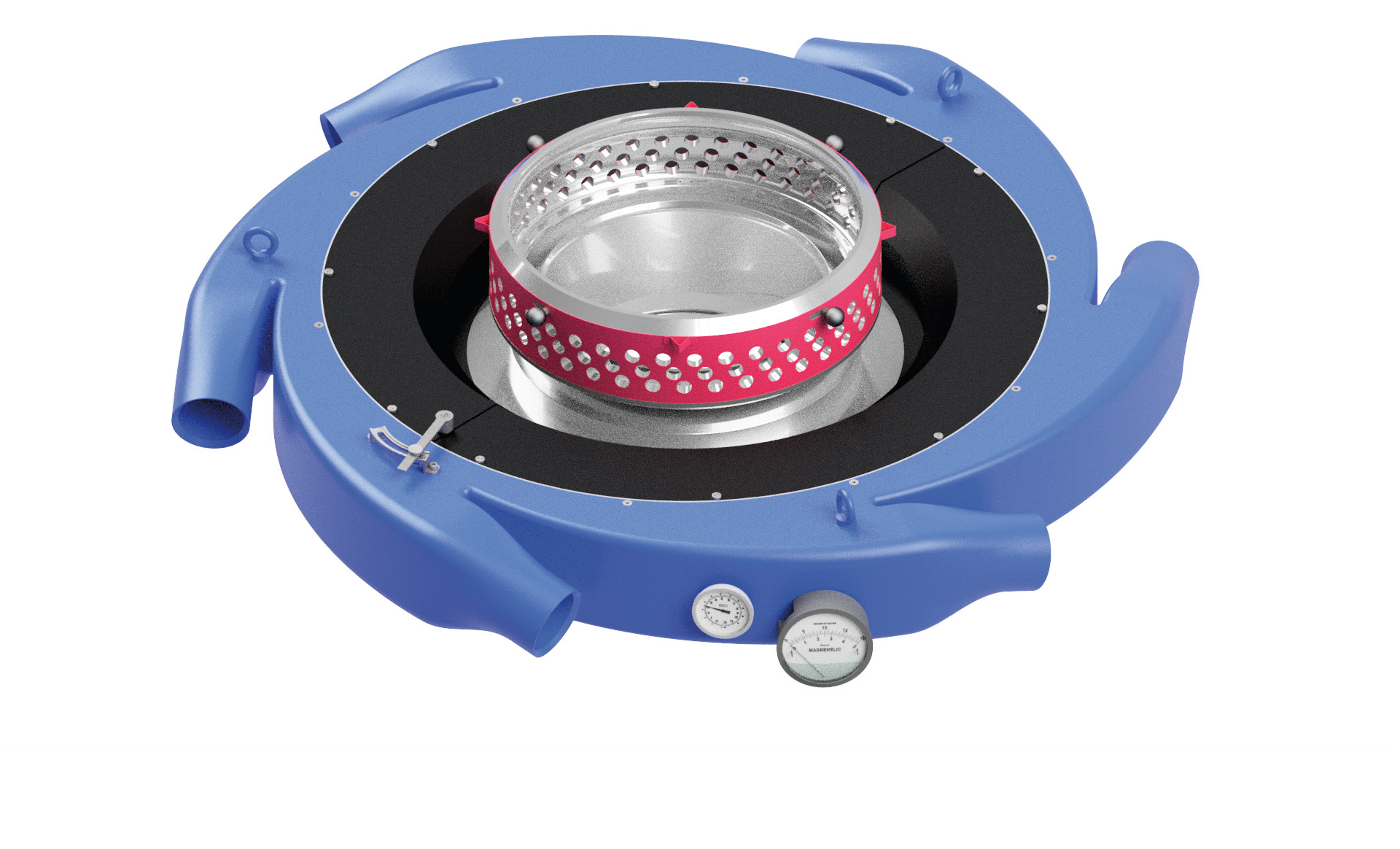

The TDK-500 Insta Gauge Automatic Air Ring provides a reliable and effective solution for controlling transverse direction film thickness, which ensures uniform profile control on blown film extrusion lines. The TDK-500 auto cooling ring quickly puts production on gauge, on time, by using a re-envisioned approach to air modulated gauge control.

See below how the TDK-500 Insta Gauge exceeds expectations in auto gauge air ring design and performance!

Faster Auto Profile Control

Video not visible? Please activate cookies to view embedded media (bottom left cookie icon).

- Secondary lip air modulation for quick, precise auto profile control of the gauge

- Low pressure design to maintain maximum cooling ring efficiency and high production rates

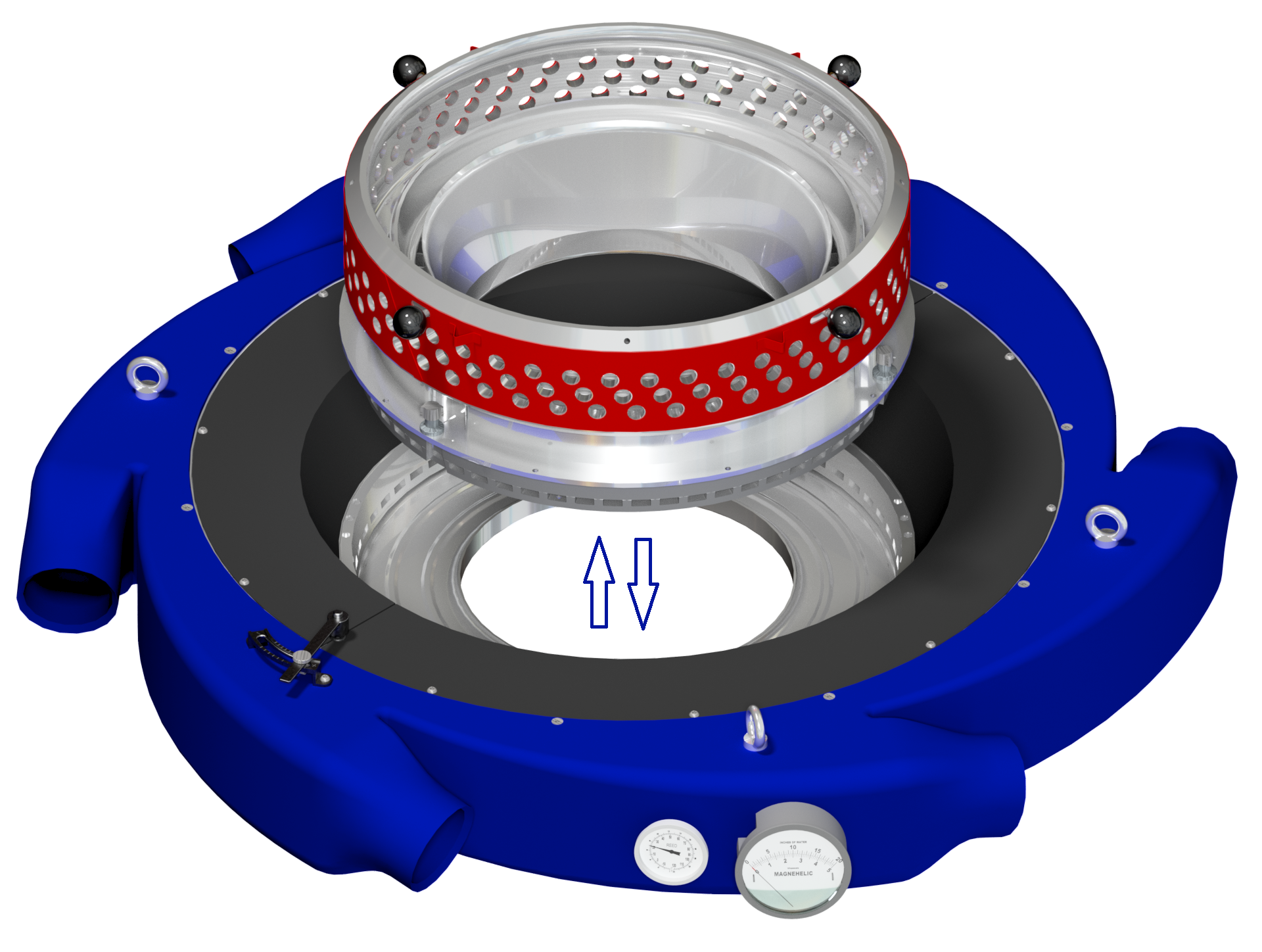

The TDK-500 improves on the implementation of airflow modulation for gauge control by using secondary lip air modulation where the velocity changes are more effective. Firstly, this leads to a quicker reaction time and higher control resolution than primary lip air modulation. Secondly this also fully permits the primary lip to achieve its job of holding a stable bubble by isolating the primary lip cooling from the gauge control air adjustments.

Flatter Film with Extrusion Profile Control

- 50% improvement in gauge variation

- Quick and reliable airflow adjustment

Controlling transverse direction film thickness significantly reduces resin costs by only producing the required film gauge. It also simultaneously guarantees that thin spots do not effect the film integrity or processability.

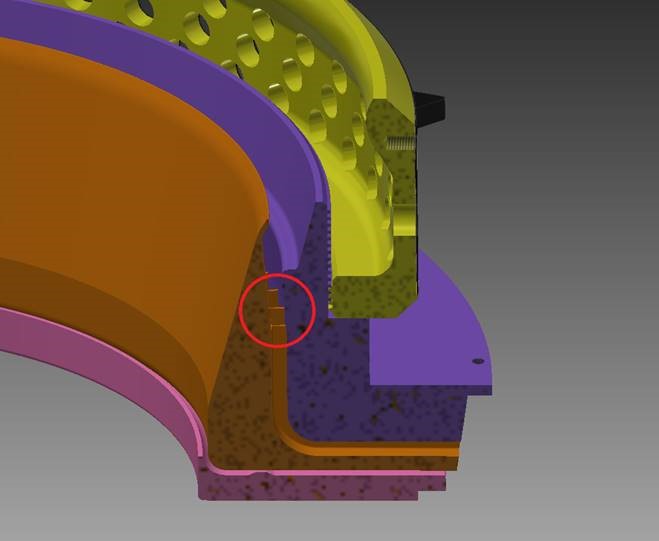

The air flow from each control zone is constrained in an independent channel that extends to just before the secondary lip exit. This eliminates zone cross mixing and provides a more direct and effective control response to the film for the best auto profile control (see orange zone, to right).

Internal components are specified to the highest degree for consistent and reliable performance, even in harsh running conditions. Safety features are built in to prevent damage and costly downtime.

Adaptable Thickness Control for Blown Film

Video not visible? Please activate cookies to view embedded media (bottom left cookie icon).

- Easy Lip Set Swap

- Adjustable forming cone

- Can be ran as a conventional air ring

- Built-in Magnehelic and temperature gauge

The unit was designed for easy component swap-out, to expand the range of products that can be ran on a single air ring.

An example of this advanced design is the facility of a toolless lip set swap. The lip set can be instantly swapped without tools, and without elevating the air ring off of the die; a time and cost saving measure which expands the versatility of the air ring. Optional weight reduction is available for easier lifting from a 3D printed polycarbonate cooling collar.

This level of modularity also drastically reduces the required effort to clean the die.

Easier Cooling Ring Operation

- Primary Lip: Single adjustment point with reference position

- User interface with 19” (482mm) color touch screen

The primary lip adjustment has been redesigned to facilitate set-up and reduce the intimidation factor of adjusting an air ring. The TDK-500 features a single adjustment point with a reference lever to adjust the primary lip, as shown to the right.

The benefit with the easy adjust lever is that there is now a reference point for the primary lip setting. This facilitates start-up by providing a setting that can be recorded and repeated for various jobs and SOP. There is no guess work involving the current set point for the primary lip with a visual reference marker.

Adjusting a blown film cooling ring just got easier.

Modular Design

The air ring features a tool-less access method for cleaning the narrow primary lip exit after process residues build up. In addition, the entire lip set can be removed and replaced in a matter of minutes while the air ring remains installed on the die. This gives the cooling ring the industry’s best flexibility in production versatility for auto profile control air rings!

Operator Friendly

As always with D.R. Joseph interfaces, every detail has been carefully thought out to provide an intuitive user interface and a control design that is reliable, easy to understand and troubleshoot. The TDK-500 control system can also be seamlessly integrated with the DRJ 3G IBC Control System for a single point of control for all bubble cooling!

Optimized Cooling

Drawing from 30+ years of experience & data collection in airflow analysis, the internal flow channels and gates are designed to minimize pressure drop and avoid turbulent airflow to efficiently make control changes without disturbing bubble stability.

- Talk to Sales

- Discuss Advantages and ROI

- Learn more about integration and features

- Receive a budgetary offer for your project

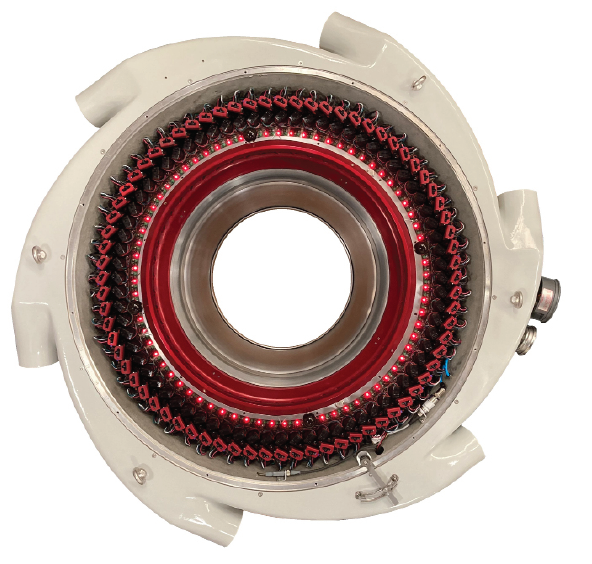

Inline Gauge Measurement for TDK-500 Automatic Air Ring

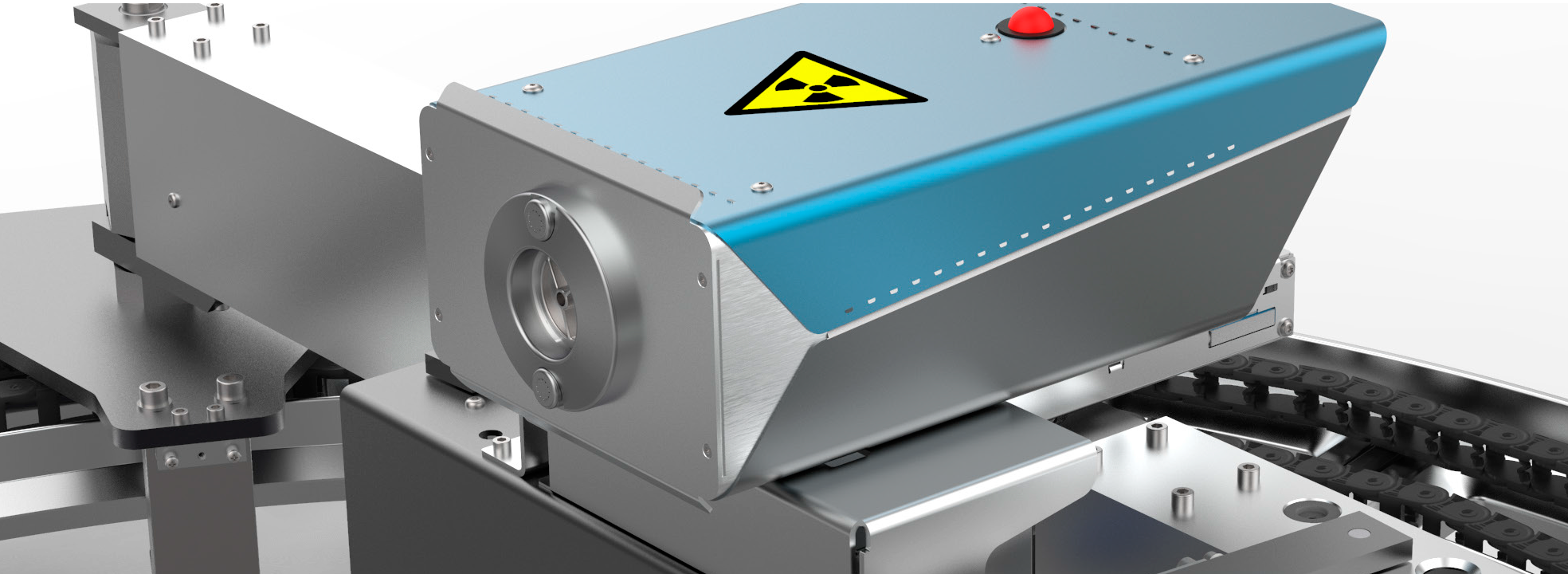

Kündig K-500 Rotomat KT Thickness Gauge

The K-500 Rotomat KT is a new, completely redesigned thickness gauge for blown film lines.

Rapid and accurate measurement of film thickness allows the film production process to be tightly controlled. As a result, film quality is enhanced and maintained during the entire production process.

Profile control with the TDK Auto Gauge Air Ring contributes to material savings. In addition, material waste during product changes is reduced.

The capacitive thickness sensor of the K-500 is protected by a cover made from sintered ceramic with a very smooth surface. That allows an extremely low wear measurement of film thickness, even though the K-500 is constantly in contact with the film.

The Rotomat KT in the third generation comes standard with a virtual data processor. The VDP Process runs in the background of a Windows PC, similar to a driver of a printer. This Win32 application forms the interface between the control system of the line and the thickness gauge.

Non contact thickness gauges are also available for sticky or touch sensitive films. Additionally, Kündig offers the K-XRAY measurement head using electrically generated X-ray to measure gauge for barrier films.

Learn More about Kündig thickness gauges!

Automatic Air Ring Experts

The TDK-500 leverages the expertise of three specialized companies; Techflow Design & Manufacturing, D.R. Joseph, Inc. and Kündig Control Systems. This unique collaboration has brought together industry leading tech to produce one of the most refined air ring solutions on the market. A seamless integration of Kündig gauge measurement, Techflow air ring design, and D.R. Joseph air flow control means that users get total control of bubble cooling with auto profile control – both Internal Bubble Cooling, and Air Ring Control, all in one spot.

Automatic Air Ring

Sustainable Blown Film Investments Focus - Cooling Ring Profile Control

Advanced gauge control systems play a crucial role in improving blown film production in several ways:

1. Sustainable Production: Accurate gauge control reduces material usage in blown film production. By precisely controlling film thickness uniformity, manufacturers reduce the resin consumption traditionally required to ensure that minimum thickness is guaranteed.

2. Flatter Film: InstaGauge uses sophisticated sensors and feedback mechanisms to monitor and adjust the film thickness continuously, ensuring flatter film. By minimizing thickness variations, manufacturers can achieve higher product quality and meet tighter tolerance requirements while also avoiding issues such as uneven sealing or poor printability. This, in turn, enhances the performance and aesthetics of the final product, meeting customer expectations.

3. More Production Hours Per Day: the InstaGauge name is a nod to how quickly the unit achieves target thickness with at least a 50% reduction in gauge variation. In as little as 5‐7 minutes, operators are in saleable production. That is less time and resin lost to out of spec material, and bonus time producing saleable product. Lower lip lock is greatly simplified with the TDK, which translates into less training, and faster start‐ups.

4. Process Stability: InstaGauge provides better process stability by compensating for external factors that can impact film thickness variation, such as die gap variation or ambient temperature. By auto‐ adjusting parameters, the system maintains stable production conditions, reducing the risk of defects and ensuring reliable and repeatable results. Additionally, operators can visualize and analyze key production parameters, such as film thickness profiles, trends, or statistical data. This information helps identify process variations, optimize settings, and make data‐driven decisions for process improvements.

5. Production Flexibility: The TDK500’s modular construction allows for fast and simple lip set swaps to expand the range of blow‐up ratios that the unit will support. This versatility allows for greater production flexibility and the ability to meet diverse market demands on one line, with one air ring.