Bubble Cages, Sizing Cages, Calibration Baskets

In the blown film extrusion process, bubble cages (aka sizing cage, sizing basket, calibration cage or calibration basket) is used to stabilize the blown film bubble directly over the die and air ring. Keeping the bubble stable with a bubble cage over the die and air ring improves film quality by ensuring the air ring and internal bubble cooling effects are uniformly applied to the entire circumference of the bubble.

As production rate increases, and in particular, when internal bubble cooling is used, the sizing cage is a required feature. The higher production rates require more air flow on the bubble which results in bubble movement and sometimes complete instability.

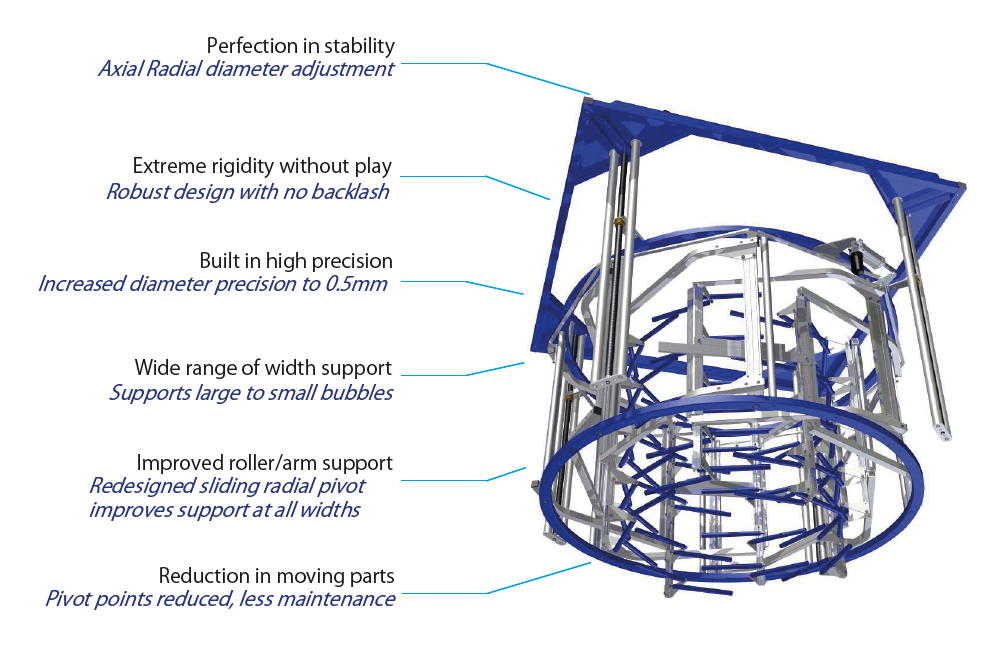

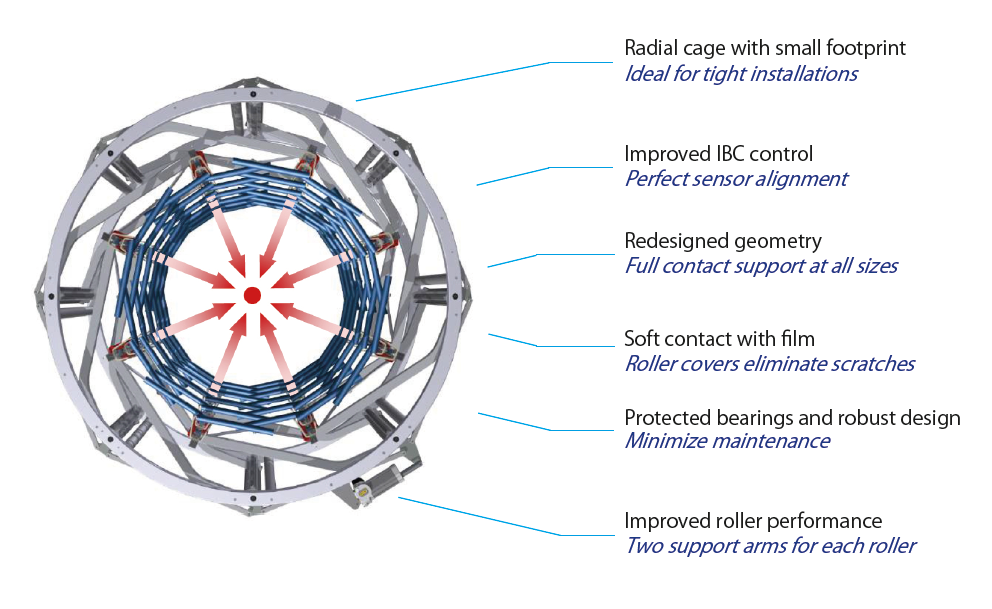

Radial cages have the distinct advantage of providing completely centered and linear support for their complete range of layflat widths. Traditionally this benefit came at the expense of added cost, complexity and a larger footprint, troublesome for tight installations.

The Roll Radial Cage improves upon the scissor cage design, while increasing the range of supported layflat widths (4:1), and maintaining the small footprint of iris style cages.

Mechanical linkages and moving parts have been greatly reduced, bringing with it the advantage of complete rigidity and zero backlash. The result is a fully supported bubble at all times. With the axial roller diameter adjustment, IBC control is also improved where the sensors are now perfectly perpendicular to the film surface at all layflat widths.

Video not visible? Please activate cookies to view embedded media (bottom left cookie icon).

Video not visible? Please activate cookies to view embedded media (bottom left cookie icon).

Bubble Cage Roller Styles: A Solution for All Types of Films

Secondary Bubble Cages / Sizing Cages

Secondary bubble cages are important, and especially critical on tall blown film towers, to keep the bubble centered in place before it enters the haul-off unit. Secondary cages are typically configured with 8 arms per level, and 2-3 levels high for a cost-effective solution to securely hold the bubble in place. |

These secondary cages maintain the same robust construction and soft roll style rollers as found on the primary cage. Motorized diameter adjustment is controlled by a UL certified control box, to easily adjust bubble diameter as necessary. Bubble diameter support range is matched to the primary sizing cage for maximum versatility. |

Options for Bubble Cages

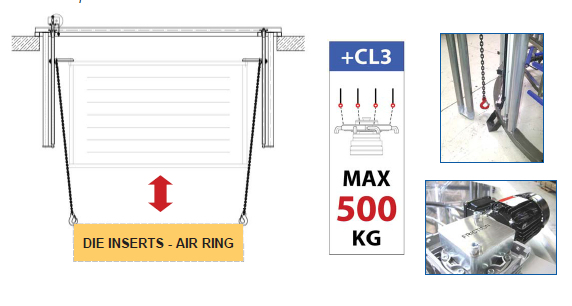

Certified Lift

The certified lifting package permits operators to use the bubble cage as a lifting crane, for weights up to 1100 lbs (500 kg), ideal for lifting components off of the die for maintenance or set-up. It is CE certified, and includes an overload safety device, lifting chains, and terminal hooks with a safety latch.

Max 770 lbs. (350Kg) : 800 – 1600

Max 990 lbs. (450Kg) : 1650 – 2350

Max 1100 lbs. (500Kg) : 2450 – 3000

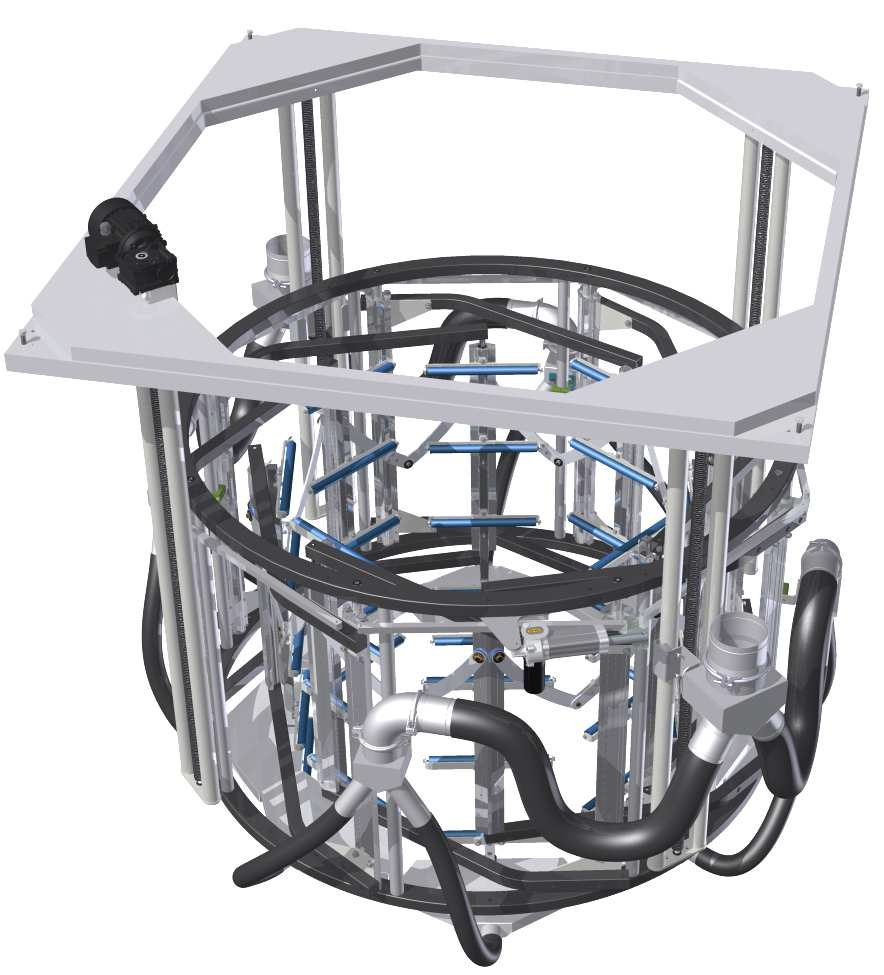

Air Exhaust System

An optional air exhaust system is available for applications that produce gas / residue as a byproduct of film production. The air exhaust package integrates suctioning exhaust vents around the sizing cage to extract extrusion fumes and contamination, which keeps the bubble and workspace free of residue and potentially harmful fumes. The system is all inclusive, coming with self-positioning suction hoods, exhaust fan, tubing, ducting and an electrical cabinet with a speed drive to regulate the exhaust blower speed. A separate filtering unit can be also included, to treat the exhaust air, and trapping the pollution. Using the highest grade of filtering materials, efficiency upwards of 90% is available with the optional filtration unit.

Trouble with tacky / sticky film clinging to bubble cage rollers? We have a solution for that!

Carbon No-Stick rollers can be fitted to our sizing cages. The light weight carbon rollers require very little inertia to spin up, perfect for thin or delicate films, while a special coating provides an extremely low COF for handling tacky films and requiring little maintenance. See a comparison of traditional Teflon rollers to Carbon No-Stick rollers: here.