Not All Internal Bubble Cooling Systems are Created Equal...

When investing in line performance, a critical component for success is the Internal Bubble Cooling (IBC) system. Less comprehensive systems of lower quality do not deliver on improved production rates, width tolerance, bubble stability or ease of use. To solve this, D.R. Joseph provides the highest quality system on the market. It is equally important on a mono layer line as it is on an 11-layer line.

The latest 3rd Generation Internal Bubble Cooling system from D.R. Joseph can improve production rates by 15 – 40% when adding IBC to a blown film line. It offers 8 – 15% improvement in production over competing IBC systems on the market. Rate and layflat tolerance improvements are achieved by automating the tough jobs with proprietary control algorithms and patented processes. Beyond rate and width tolerance improvement, you can also expect:

- Powerful technology that quickly makes your new operator nearly as good as your experienced operator.

- Flexibility to run the widest range of materials of any system on the market, from .3 mil to 100 mil, from HDPE to exotic materials.

- Remote service support leverages our expertise to solve your problem in a matter of minutes.

- Reliability in any environment around the world, flexible configurations, and bullet proof components.

Watch a quick video describing what Internal Bubble Cooling is, and how it works here.

Expect More From Your Internal Bubble Cooling System

- Balances flow rate of inlet/outlet blowers

- Maintains balance as process conditions change

- Reports airflow blocks/leaks

Value: Less operator intervention, consistent SOP

- “Set it and forget it” size changes and start-up

- Measured via bubble diameter for faster response

- Configurable layflat alarms

Value: Reduce waste of your most valuable resource: resin. Also reduce out of spec material

- Positions cage diameter to optimally achieve target layflat size

- Less operator intervention at start-up and quicker size changes to reduce scrap

Value: Expedites size changes, consistent SOP

Automatic Valve Calibration (patented)

- Automatically calibrates airflow control valve to any die or restrictions in air path

- Includes comprehensive airflow diagnostics to expedite troubleshooting

Value: Keeps system running in “like new” operation

Bubble Break Detection / Extruder Stop

- System detects if un recoverable bubble break has occurred

- Can send a signal to extruders to stop, to prevent die drool in a line down situation

Value: Reduces downtime and equipment damage due to unnoticed die drool

Want Even More From Your Internal Bubble Cooling System?

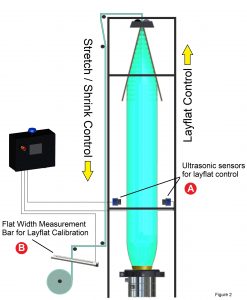

Automatic Layflat Calibration

Final roll width measured by a flat width bar at the winder is automatically calibrated to the IBC system. This accounts for film shrinkage and stretch as it makes its way down the tower. It adds to the precision, reliability and safety of the system (no more tape measure injuries)!

Neck Height Control

Ensures a consistent dart impact strength with this feature. A dedicated sensor measures the flare on high stalk bubbles while the system regulates air ring speed or temperature to ensure consistent neck height.

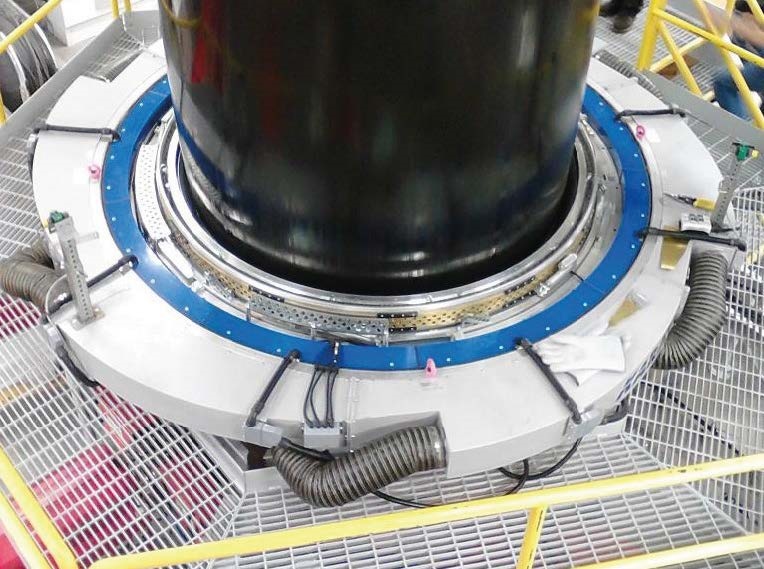

Cage Height Management

Allows users to preselect various cage height positions (per running conditions of various jobs or even for line maintenance). Then sends the cage to the predetermined height with the tap of a button.

Data Logger

Record and export IBC process data in .csv format via built-in FTP. By logging this data to a spreadsheet, or viewing via DRJ’s LogViewer program, users can track production and IBC process conditions to evaluate machine productivity, troubleshoot problems, validate SOP and supply customers with a second point of quality control.

WinViewer

Adds a second remote point of control for DRJ IBC Systems. Requires a PC based operation point, which then replicates the DRJ HMI controls for full remote capability.

Geo / Ag Internal Bubble Cooling Control

For large geomembrane cooling control, one size does not fit all.

So it is not a surprise that standard Internal Bubble Cooling control systems do not fully meet the demands for control of Geo / Ag film extrusion.

The solution from D.R. Joseph is the Geo/Ag IBC Control System, a system designed to collect data and control the bubble differently than any IBC solution on the market. Key features are a special control algorithm designed around the specific process dynamics of large bubbles, special sensor placement around the bubble, oversized flow control equipment and on the fly tuning of a second, final measurement point.

Many DRJ IBC control features are carried over from the standard DRJ IS-IBC system, such as automatic start-up, auto layflat control, statistical reporting and bubble break detection.

How It Works

Fixed position Geo sensors read the bubble diameter just above the air ring. The system uses a special algorithm to automatically set the distance between the geo sensors and the bubble to achieve the target width. A second set of fixed position sensors above the frost line read bubble diameter and calculate the layflat. The controller retunes the geo sensors to bubble distance on the fly to ensure the target is maintained as thickness and materials change. The BUR range for this system is 0.98 – 1.50.

3rd Generation Internal Bubble Cooling Updates

D.R. Joseph has been producing and developing Internal Bubble Cooling Control Systems for over 30 years now. Over time, there have been many improvements and customer driven solutions. For those who have older first and second generation systems, below is a look at what is new.

3rd Generation IBC Updates

Knobs and switches have been replaced with full touch screen control. A larger 8” color touch screen is new for 2020. The IBC touch screen is now a single point of control for IBC, Blowers, Sizing Cage, and flat width bar, if integrated.

This highly visible xenon lamp flashes based on a configurable set of parameters. The parameters allow management to be alerted whenever the operator uses the system in a manner outside standard operating procedures (for instance, running the system in manual layflat control when the SOP requires running in automatic layflat control) or when there is an internal or external fault. This is particularly useful in the case of a bubble break. The beacon relay can also be wired to trigger an audible alarm.

Air flow related issues make up more than half of the service calls that DRJ takes. Restrictions in airflow can be related to a clog, a collapsed hose, dirty air filter or a leak in the ducting. These sort of issues cause bubble instability, and are often overlooked by maintenance personnel. The 3G IBC system will now detect and point users to the specific airflow path that is blocked.

Another maintenance issue that is often overlooked is the periodic calibration of the bladder valve. The system will now calibrate the valve as required without the operator having to make any special steps. This eliminates the need for maintenance to manually adjust the system when there are subtle or significant changes to the die or air flow path.

3rd Generation IBC Updates

The IBC system has installation requirements that are often overlooked by a less-experienced engineer. For instance, installing the layflat sensors in the proper position to handle all possible bubble sizes, or setting up the bubble break detector distance, or establishing the final blower ratio. We’ve added new features that assist or automate the process with guidance details, so less time is spent getting these features properly commissioned.

Whenever we produce a new system, we do everything possible to protect our existing customers’ investment. The 3rd generation ISIBC1 is no exception. We’ve made the 3rd generation software so it can run on previously installed 32 bit systems. This means that adding automatic valve calibration only requires replacing the touch screen and installing electronic Magnehelics. Please note that 8 bit systems cannot be upgraded unless the 8 bit controller is replaced with our 32 bit controller.

There is nothing more involved for the customer than to configure and validate data integration. Regardless of the integration level, the IS-IBC1 system can support it. Standard interface protocols are Modbus TCP over Ethernet, and Modbus RTU over RS232, and a wide variety of industry standard protocols enabled through an optional protocol converters. Each system comes standard with an Ethernet switch for integration and remote support.

This feature allows the IS-IBC1 to be fully integrated into any OEM extrusion line control system.

Absolute Width Control / Calibration (Optional)

Automatic Layflat Calibration (ALC) is a new optional feature for the DRJ IBC Control System and nonIBC Width Controller. It utilizes a flat width measurement bar placed near the winder to automatically calibrate and compensate for film stretch and shrink as it makes its way down the tower.

A host of factors cause varying degrees of stretch and shrink which effect the width as it is wound. Utilizing ALC is the next step in providing customers with ultra-precise layflat tolerances by simplifying width management operations via automation and improving user safety. For production where job orders change often, ALC speeds up job change time and improves long term accuracy.

Improve long term accuracy: Automation that accounts for film shrinkage / stretch

Final film width after the primary nip of a blown film line is dynamic; as the film makes its way down the line, various factors effect the actual film width as it is wound on the core. Film shrinkage and stretch occur at changing rates due to the following factors:

- Web Tension

- Polymer Properties

- Film Gauge

- Film Temperature

- Ambient Temperature

- Factory Pressure Change

For precision width control, the layflat system must be calibrated to account for shrink / stretch. The Automatic Layflat Calibration (ALC) feature acts as a final QC checkpoint to correct the layflat system, compensating for previously uncontrolled variables.

For production where job orders change often, ALC speeds up job changes, saving time, saving scrap and keeping the roll precisely on the customers specification.

How it Works: Two Points of Measurement

Layflat control is carried out by ultrasonic sensors as shown on point (A), (shown above). They are strategically placed to make timely adjustments to layflat variances, thereby avoiding control lag. Here, the system adjusts for air loss in nip leaks and pin holes, or layflat gain due to internal thermal expansion or ambient temperature changes.

Point (B) shows the second measurement point via the FE-8 width bar. It is strategically placed to account for stretch / shrink of the web as it comes down the tower. It adjusts for shrink variance due to material, gauge, job size (width) and temperature changes.

Final width as measured by the FE-8 is automatically calibrated to the width control system.

Neck Height Control (High Stalk Bubbles) Optional

Automatic Neck Height Control for HDPE / MDPE High Stalk Bubbles for improved / consistent film properties and production.

Neck Height Control is an optional add-on feature for the DRJ IBC System which manages layflat width.

How it works

The control feature uses an ultrasonic sensor facing the bottom of the bubble flare to measure neck height, then maintains the set point to within +/- 0.25 inches (6mm) via regulating the air ring blower speed. Neck Height Control is also dependent on feedback provided from the IBC layflat sensors for complete bubble control.

Together with the Internal Bubble Cooling System, it manages both layflat and neck height during startup, hole recovery and normal production. This coordination reduces time to production and improves production rate. When both width control and neck height are easily and automatically controlled, operators gain the confidence to increase extrusion speed without fear of losing bubble control or producing out of spec film.

Integration

Neck Height Control requires and integrates with automatic width control from the DRJ IBC system. Integration to the air ring blower (varying blower speed to control neck height) is via standard serial data communication to a Yaskawa A1000, P1000 or V1000 inverter.

Benefits to Implementation

Controlling and maintaining neck height on high or medium stalk bubbles directly correlates to improved consistency in HDPE / MDPE film dart impact and other film properties related to neck height. Beyond consistent film properties and elimination of dart impact failures, benefits that customers can expect include increased production rate due to improved bubble control and tighter layflat control due to the IBC systems automated width control.

Sustainable Blown Film Investments Focus

Precision control of film width in blown film extrusion directly correlates to resin savings and reduced

waste, meeting criteria for sustainable production investments.

An opportunity to reduce resin consumption via width control on blown film lines is an excellent avenue

to meeting sustainability objectives. Many lines, especially those without internal bubble cooling (IBC)

control, have no, or rudimentary width control systems in place. In these scenarios, production will

produce a width larger than necessary and take edge trim to guarantee that target width is achieved.

Reducing the edge trim with width control systems is both profitable, and a quantifiable investment in

sustainable production.

Width control reduces resin consumption in the following ways:

‐ Eliminate or reduce trim on sheeting

‐ Reducing waste production by automating width control on start‐ups and job change‐over

‐ Avoid order returns due to width deviation

‐ Prevent die drool by enabling extruder‐stop when no bubble is detected by the system

Especially in the case of barrier or co‐extrusion production, eliminating or reducing trim which often

cannot be reprocessed is meeting sustainability objectives in two ways – reducing waste, and reducing

energy consumption otherwise allocated in the production of the aforementioned trim.

To put the resin waste into perspective, case studies show that edge trim on a line without width control

amounts to 13,225 lbs. (6000 kg) for a 3 mil (75 micron) film over the span of a year for one blown film

line.

Post‐Consumer Recyclete (PCR) multiplies the challenge of keeping a consistent width and stable bubble

due to contaminants, variation in quality and material composition. These inconsistencies add

challenges to holding tight layflat. Automating width control addresses this significant challenge,

making sustainable production with PCR a viable option.