Frematic IBC Upgrade: Eliminate Film Marks, Breathing and Low Production Rates

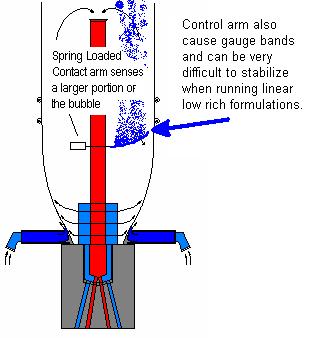

Mechanical arm control systems such as used in the past by Frematic for Internal Bubble Cooling (IBC) are problematic for linear low and metalocene rich fomulations. Particularly when running materials less than 1 mil (25 microns).

In addition, the contact arm can actually mark the film because of the high spring tension required to keep the arm from skipping over the film. Users often are forced to run the film tight in the cage to keep the film stable, with the side effect being marks in the film.

Eliminate the film marks, breathing and low production rates by upgrading to an IS-IBC1 non-contact ultrasonic IBC control system from D. R. Joseph. With 30 years experience in the field of IBC controls you can be sure to get the best performance available.

Beyond implementing a more reliable solution with available support and spare parts, users report up to 15-20% improvement in bubble control and production rates, thanks to higher IBC cooling rates, and a finer layflat control.

DR Joseph specializes in IBC system upgrades: our systems integrate and perform on virtually any blown film die on the market. A thorough airflow load analysis is performed on a die to die basis to understand how our system must be configured to deliver the best possible cooling control.

A wide variety of IBC automation features are included with the Frematic to DRJ IBC upgrade that reduce the chance of error or neglect in operation on the shop floor.

If you want to learn more about the features of the IBC upgrade, please click below.